- Find a stable method

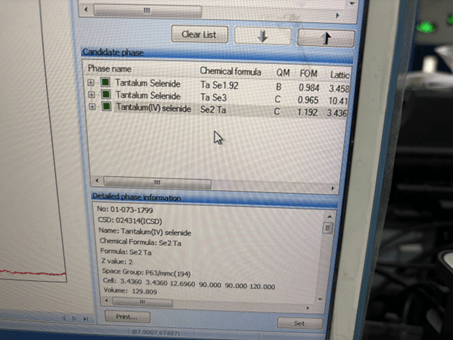

Firstly, the single crystal to be grown is defined according to the experimental needs, and the growth method is clarified through literature research and searching on the ICSD website.

For TMD materials, the chemical vapor phase transport method is generally used and is currently the only method supported in our lab. The next step is to introduce the method of single crystal growth in the lab, using TaSe2 as an example.

Fig 1. Example of growth 1T-TaS2-xSex

2. Get the polycrystalline and check it

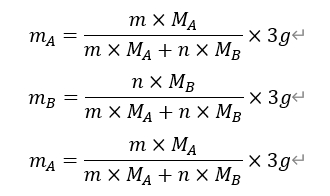

The first step is to grow polycrystalline material using monomers of both elements. Calculate how much of each of the two elemental monomers is needed for a sample with a total mass of 3g (Suitable for crucible) according to the stoichiometric number comparison.

Suppose there are two elements A, B for AmBn, whose relative atomic masses are MA and MB respectively. Over there A and B should take the masses mA and mB respectively.

We weighed it using an electronic balance to 3 decimal places and then poured both the weighed A, B into a small aluminum oxide crucible. Select a glass tube, pad it with quartz wool underneath, and place the alumina crucible in it with the opening facing up.

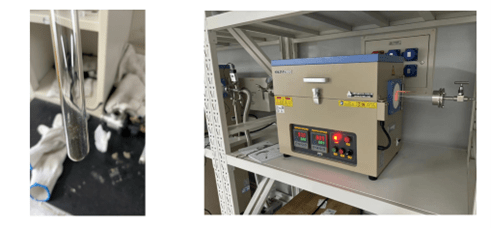

Fig 2. Details of the growth process

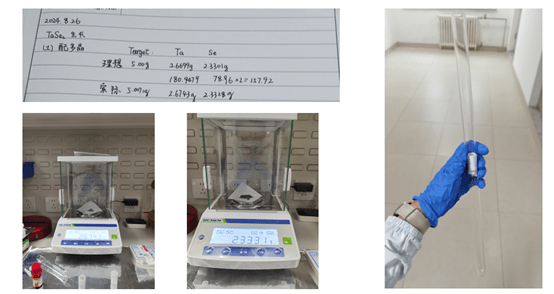

After all the above preparations, go to E308 of the East Building of the School of Physics to seal the tubes, and send the tubes to the furnace in B118 of the General Research Building to grow for 4-5 days.

Fig 3. Pictures of successful tube sealing and placement in the oven

3. Using polycrystalline and iodine related to volume to do CVT

After burning the paper for 4-5 days, the polycrystals were taken out to Mr. Jia Shuang’s group for XRD measurements, and it was determined that the grown polycrystals were of high purity and were what we needed.

Fig 4. XRD test results

Find a 50cm long tube and put the iodine(calculate by the method the part 1 given) and polycrystals into the bottom of the tube. Be careful not to contaminate the walls of the quartz tube, otherwise it will be difficult to seal it. After that, seal the tube and send it to the tube furnace in B118 of the General Research Building for 10 days or longer according to the growth temperature.

Fig 5. Tube Furnace Growth

4. Determination of the purity of the samples obtained by XRD

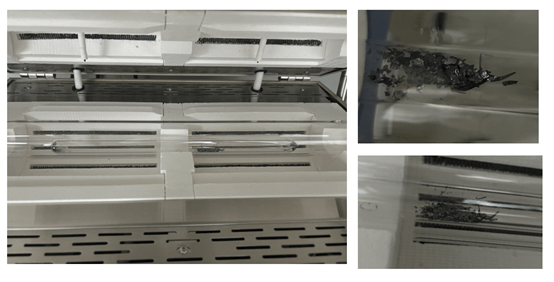

After waiting ten days, the samples are removed, the single crystals that work are selected, and the rest are thrown away. XRD measurements were again used to determine the purity of the single crystals and the specific direction

Fig 6. Pictures of grown single crystals

Special thanks: Ms. Jia’s subject group, Zeyu Ma, for teaching and helping to seal the tubes!